Written by Dr David Kyle

Head of Software

Field Oriented Control: Precision in Modern Motor Systems

In modern engineering, precision motion doesn’t just happen – it’s designed. Field-oriented control (FOC) has become the standard method for driving brushless DC motors (BLDC) and delivers smooth, efficient, and responsive performance. Many off-the-shelf controllers already use it, but when a product demands more than generic control can provide, implementing and tuning FOC becomes a specialist challenge. That’s where Plextek’s experience in firmware, electronics, and system integration makes the difference.

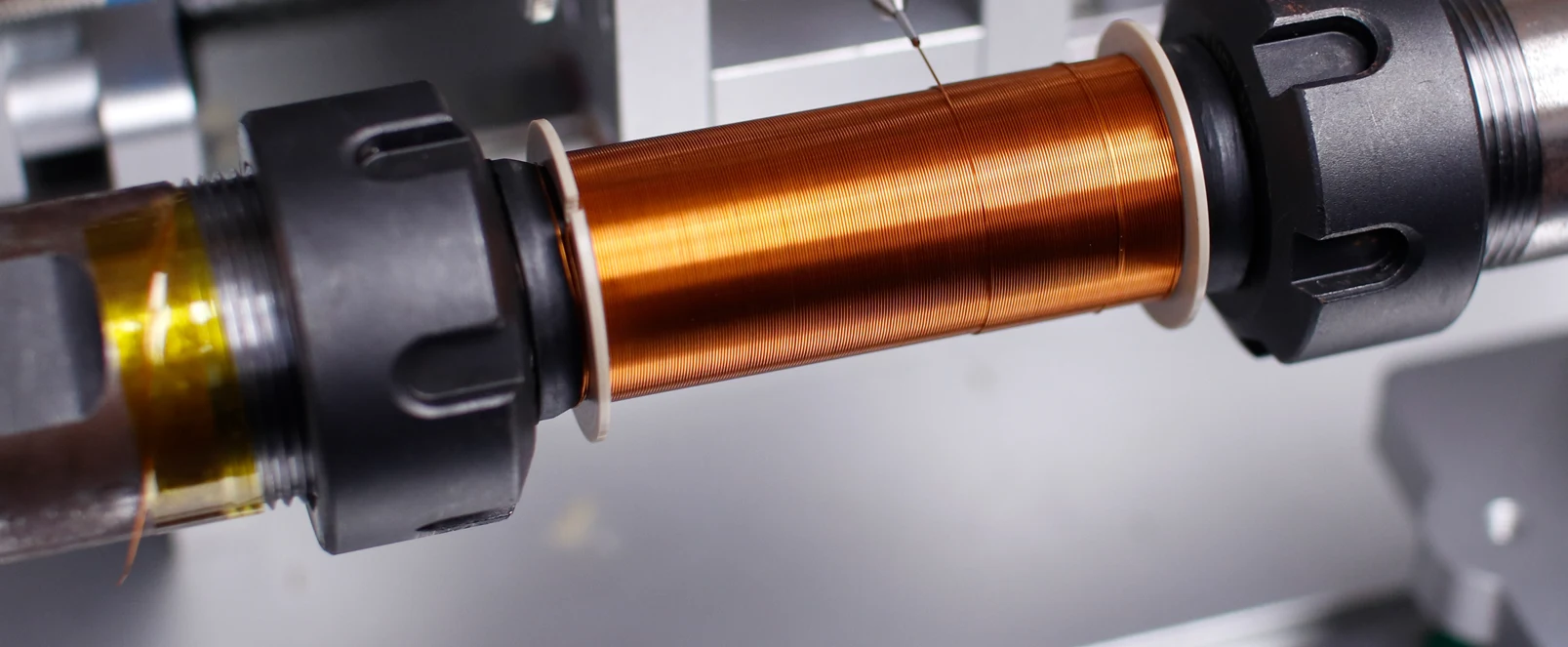

Historically, electric motors relied on mechanical commutation using carbon brushes, resulting in sparking, heat, and wear. By contrast, advances in permanent magnet materials, power electronics, and embedded control systems have eliminated the need for brushes entirely. Electronic commutation can now generate the required rotating magnetic field, and by using rare-earth permanent magnets in the rotor, we can produce torque with precise control and greatly improved overall efficiency.

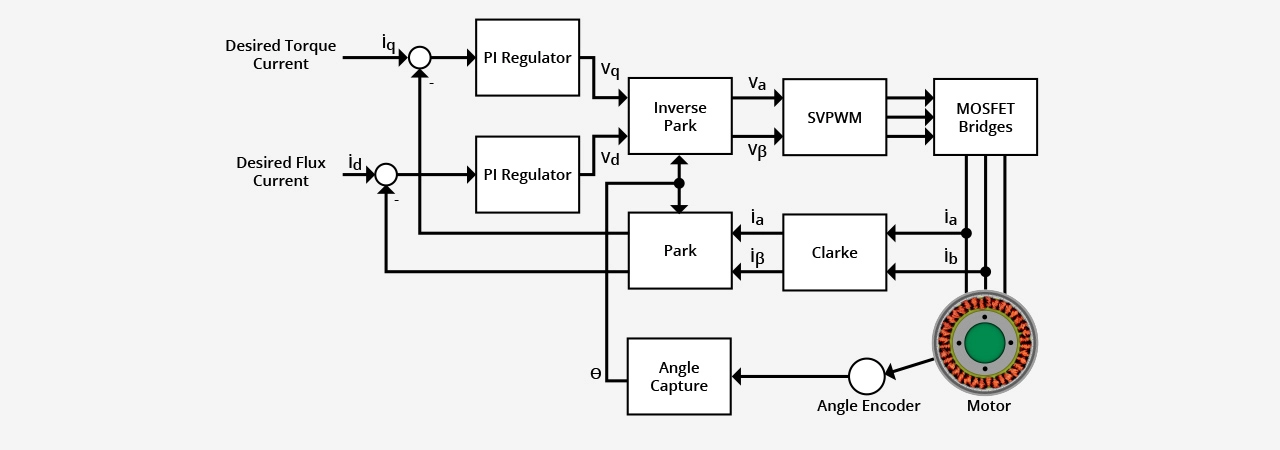

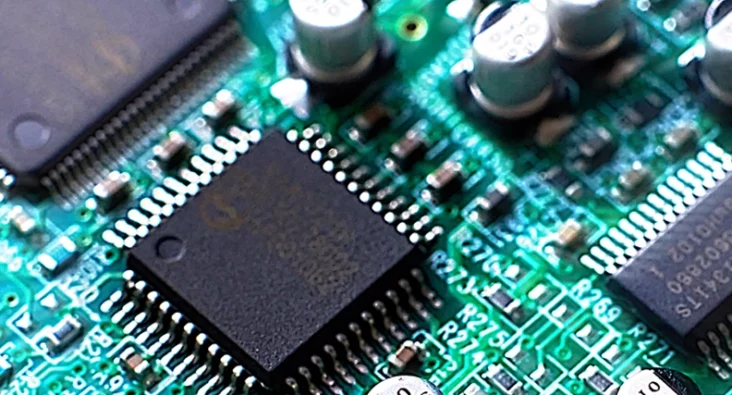

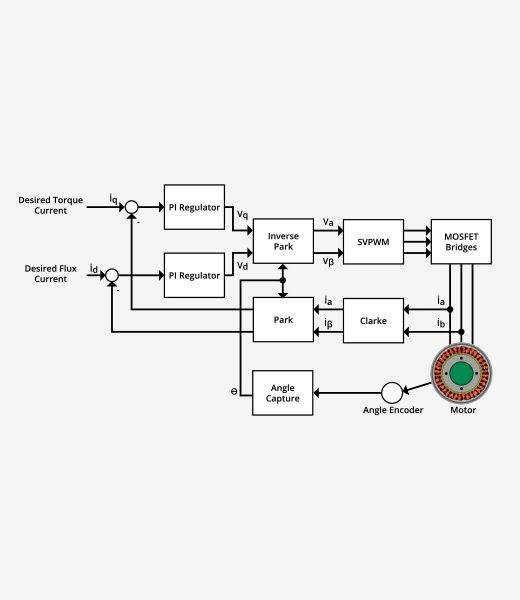

However, while the principle of FOC is elegant, its implementation is complex. It requires an understanding of Park and Clarke transforms, PID control, space vector modulation, rotary encoders, power electronics, and a solid grounding in embedded development.

For many applications such as drones, e-bikes, or handheld power tools, off-the-shelf motor drive systems are sufficient. But in more demanding or specialised use cases, standard solutions rarely deliver the required performance. Silicon vendors such as STMicroelectronics and Microchip provide comprehensive FOC reference implementations, yet turning these into production-ready, fully integrated solutions requires embedded expertise and system-level engineering capability

Case Study

Plextek has been working with iFIT, a global leader in connected fitness technology, and Beeleader, a mechatronics company specialising in sports science and health-focused motion systems. For iFIT, we developed, in partnership with Bee Leader, a custom motor control solution for their exercise equipment, where the performance requirements went far beyond basic motion control. The controller had to deliver exceptionally low torque ripple for smooth, natural resistance during exercise, while also tolerating being back-driven by the user without risking damage to the power electronics. Meeting these requirements called for careful control-loop tuning and solid embedded and electronics design, allowing the controller to function as a native part of iFIT’s system architecture rather than a bolt-on component.

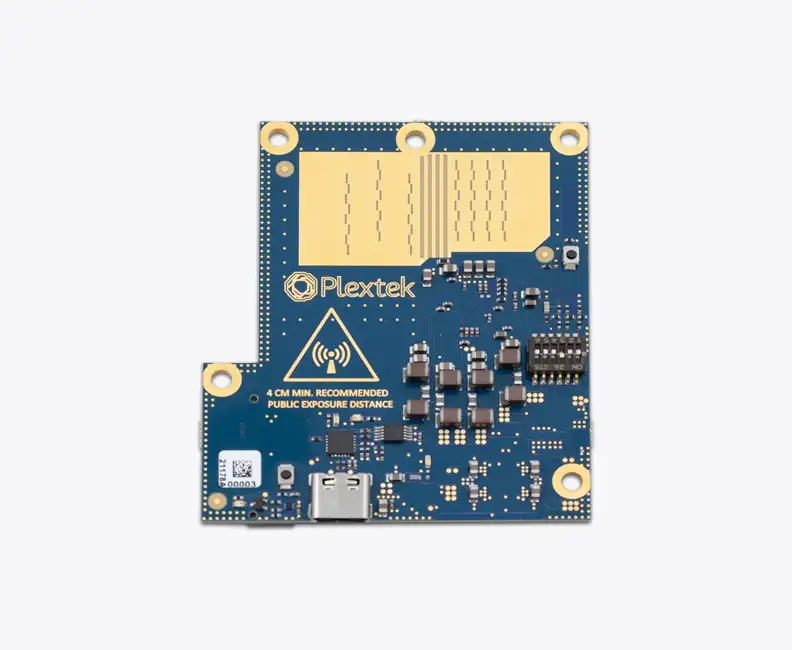

By taking on this technically complex part of the design, Plextek enabled the client to avoid a steep learning curve, reduce development risk, and retain a proven motor control design as an IP block for future products. This also freed their engineers to focus on the features and user experience that define their product, with Plextek delivering a fully integrated custom motor control PCB and firmware solution.

“Plextek delivered exactly what we needed: a custom motor control solution that met our demanding torque and integration requirements while fitting seamlessly into our existing architecture. Their expertise saved us months of development time.”

Jared Willardson, Vice President of Product Engineering, iFIT

Simulation and Analysis

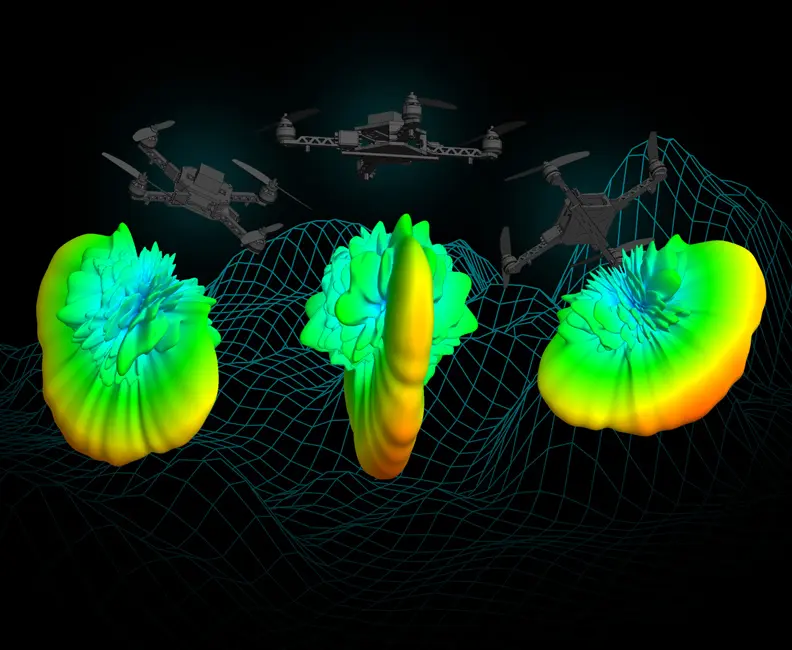

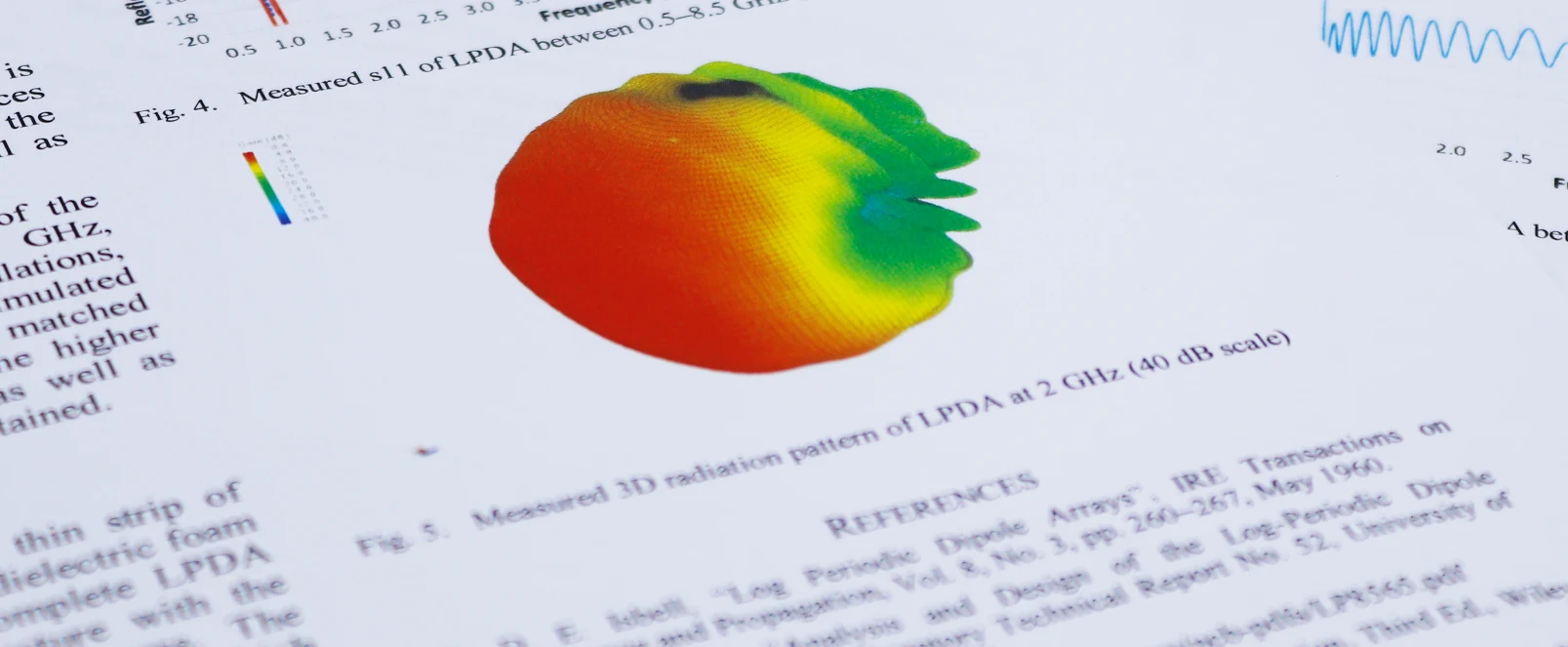

Motor control extends beyond software and electronics; it also depends on physical parameters such as magnetic flux density and electrical current. Understanding these relationships is critical when analysing real-world torque ripple or nonlinear effects such as magnetic saturation, where the magnetic core can no longer increase its flux despite higher current. This causes the motor’s response to become nonlinear, contributing to torque ripple. In this case, simulation of the motor’s magnetic core highlighted areas of saturation that helped explain observed torque ripple, guiding adjustments in the control algorithm and confirming the limits of the physical design.

Validation and Closed Loop Testing

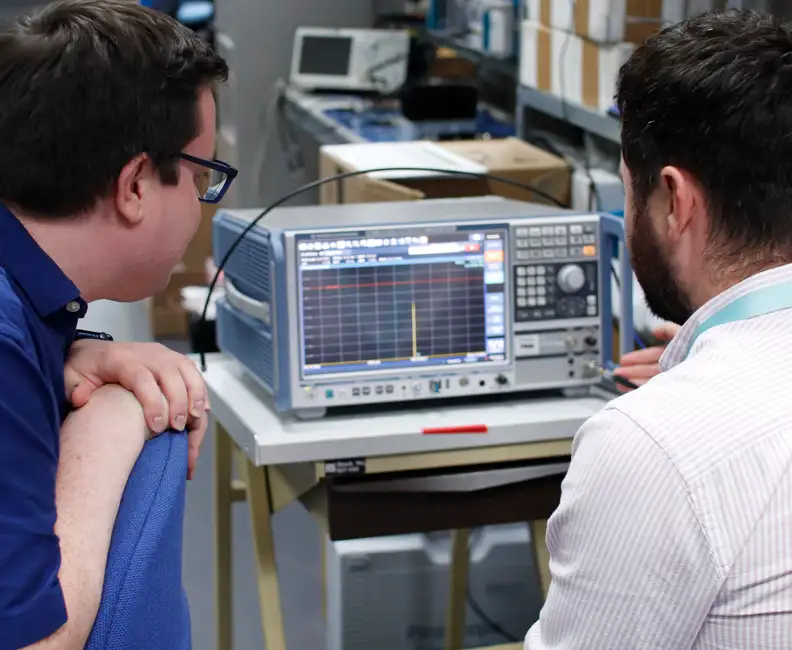

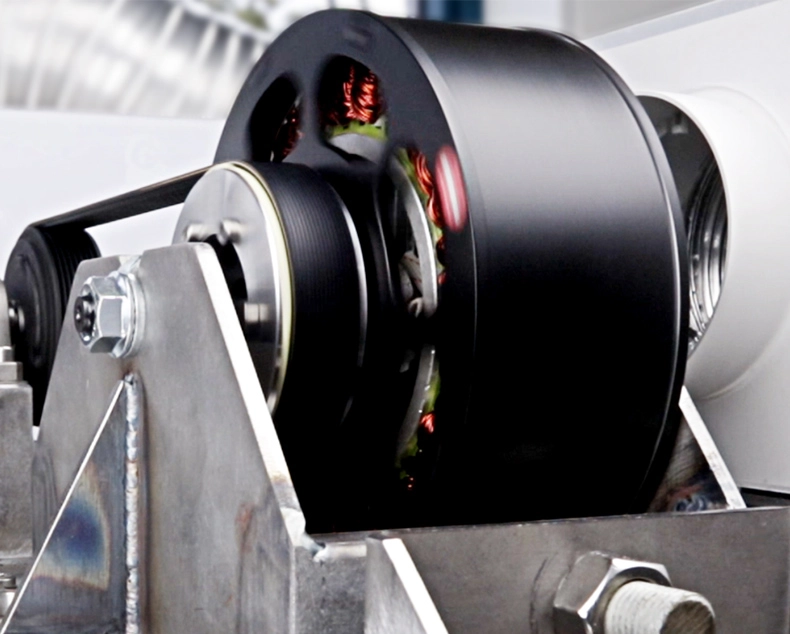

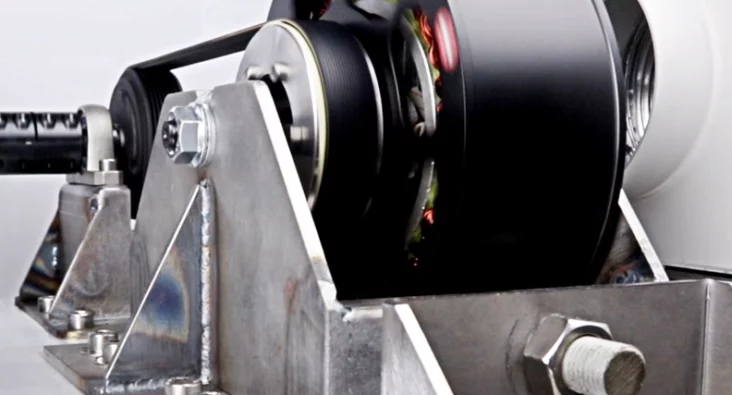

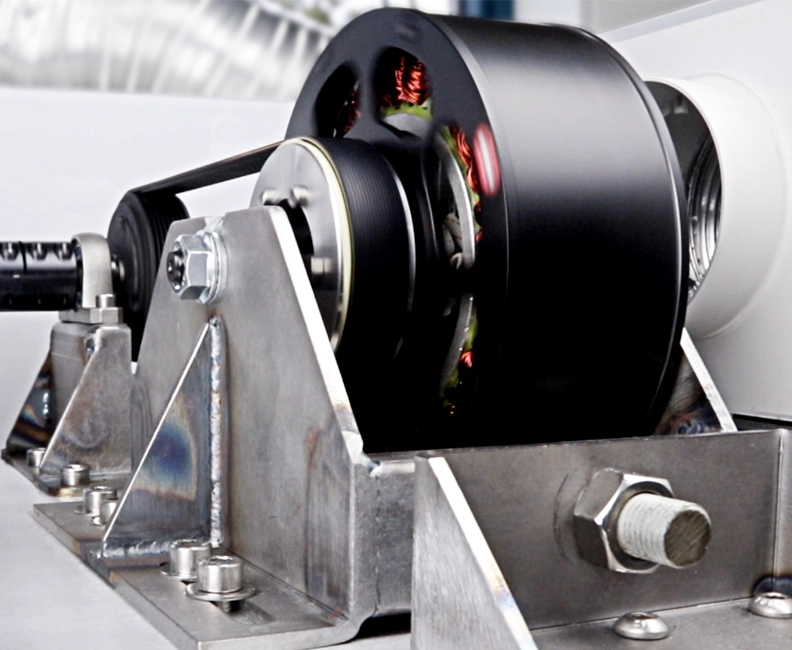

As with any embedded software and electronics development, validation is essential. The controller and motor must be proven to operate reliably together under both normal and corner-case conditions. To achieve this, Plextek designed and built a custom mechanical test rig capable of fully automated, Python-script-driven, repeatable testing.

Using torque, temperature, and speed sensors, the system exercised the motor across defined control profiles and varying loads over extended test cycles. This empirically verified stable operation, accurate torque response, and thermal performance, giving confidence that both the control system and mechanical hardware met specification and maintained reliable performance.

Shown above: Motor controller mechanical test rig and finite element brushless motor simulation indicating magnetic flux density

Motor Control Expertise

This project demonstrates how specialist knowledge in FOC control for BLDC motors, combined with practical embedded and electronics experience, enables us to solve demanding motion control problems that go beyond standard drive solutions. The same capability applies wherever precise, efficient and reliable motor control is critical.

In medical devices, smooth, quiet and predictable motion is essential for patient safety and user confidence. In industrial automation, precise torque and position control improve repeatability and throughput. In robotics, real time control and system integration are key to dynamic performance. And in consumer and fitness products, refined motion control can be the performance differentiator that defines product quality.

Plextek’s cross-disciplinary team combines expertise in embedded systems, motor control and system integration to help clients achieve this level of control in their own applications, whether through complete custom solutions or by integrating proven designs into larger systems.

Facing similar challenges?

With 35 years of experience delivering complex engineering solutions, Plextek has developed embedded motor control expertise for medical, industrial, and consumer applications.

Our cross-disciplinary team combines embedded systems expertise, motor control knowledge, and system integration experience to deliver production-ready solutions that meet demanding specifications. Get in touch to discuss your motor control requirements: