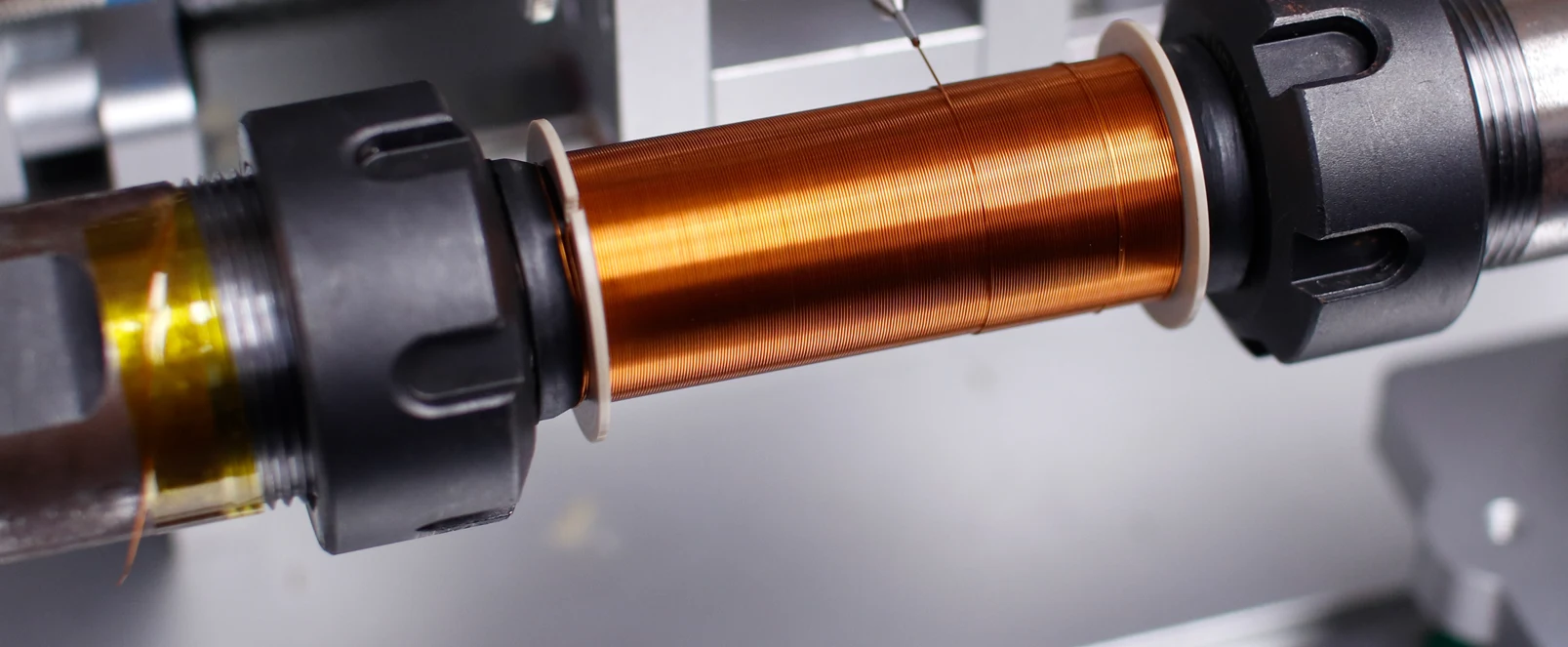

Manufacturing

01 / 03

02 / 03

03 / 03

Technology Platforms

Plextek's 'white-label' technology platforms allow you to accelerate product development, streamline efficiencies, and access our extensive R&D expertise to suit your project needs.

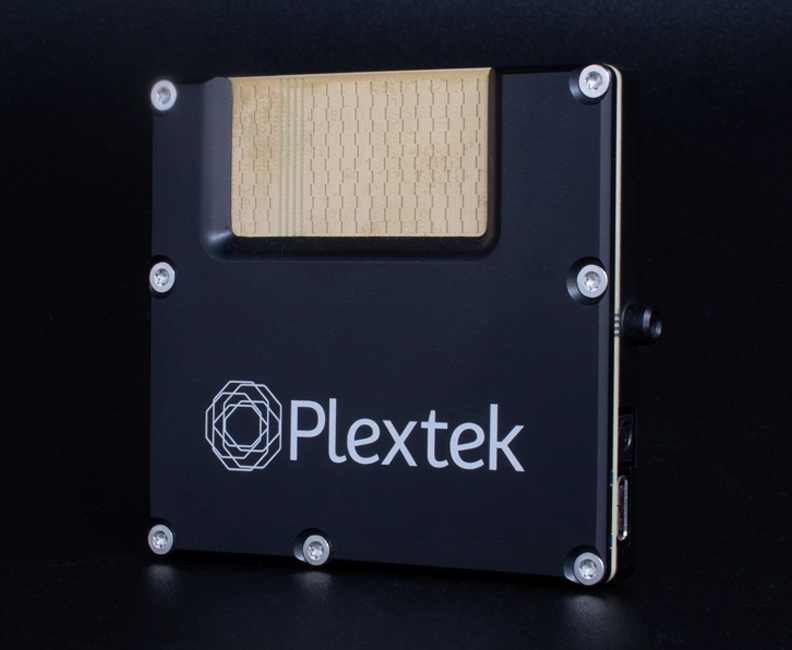

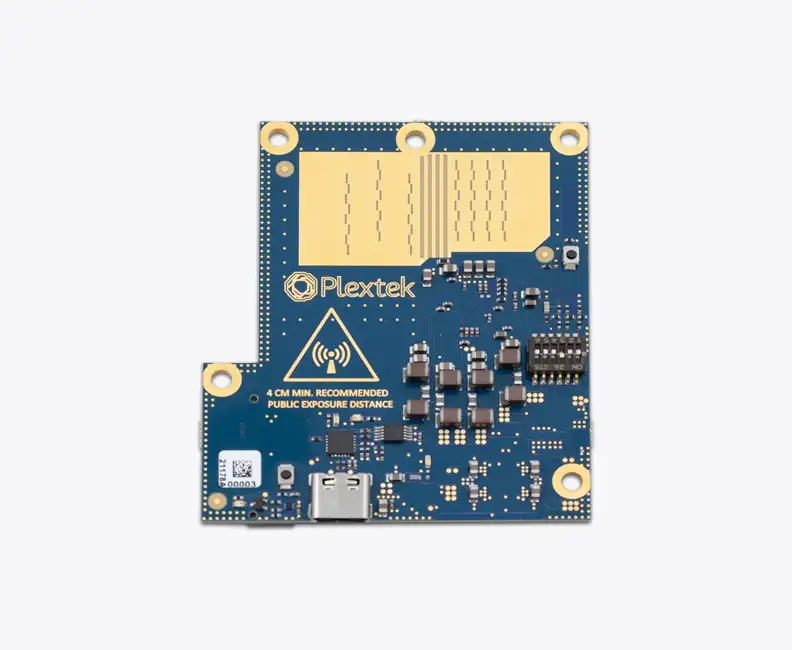

- 01 Configurable mmWave Radar ModuleConfigurable mmWave Radar Module

Plextek’s PLX-T60 platform enables rapid development and deployment of custom mmWave radar solutions at scale and pace

- 02 Configurable IoT FrameworkConfigurable IoT Framework

Plextek’s IoT framework enables rapid development and deployment of custom IoT solutions, particularly those requiring extended operation on battery power

- 03 Ubiquitous RadarUbiquitous Radar

Plextek's Ubiquitous Radar will detect returns from many directions simultaneously and accurately, differentiating between drones and birds, and even determining the size and type of drone