View a selection of our latest articles and downloadable content including brochures and technical papers.

Projects

- All Engineering Expert Areas

- All Technology Platforms

- All Markets

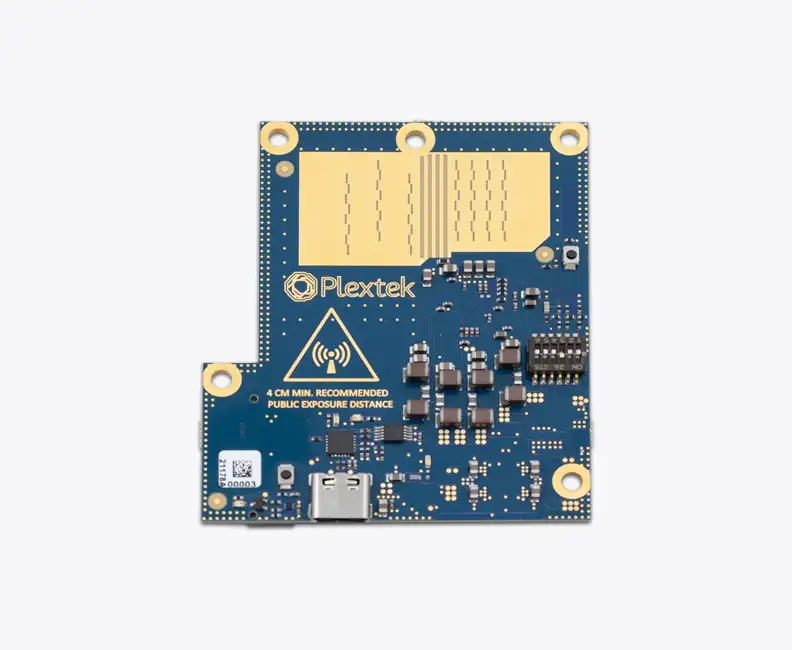

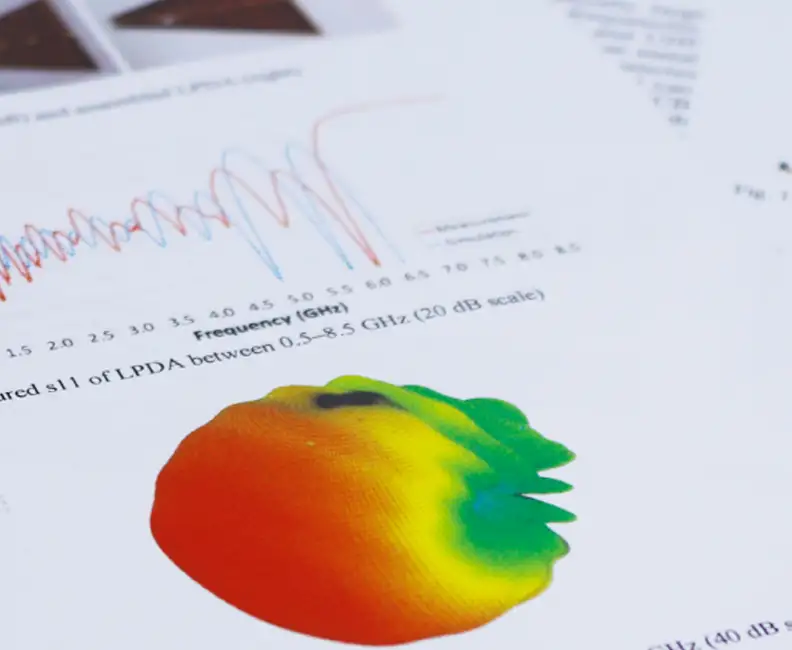

Game-Changing Radar for the CLEAR Mission

Developing vital radar technology for the CLEAR mission, advancing space debris removal techniques to safeguard operational satellites and spacecraft.

Insights

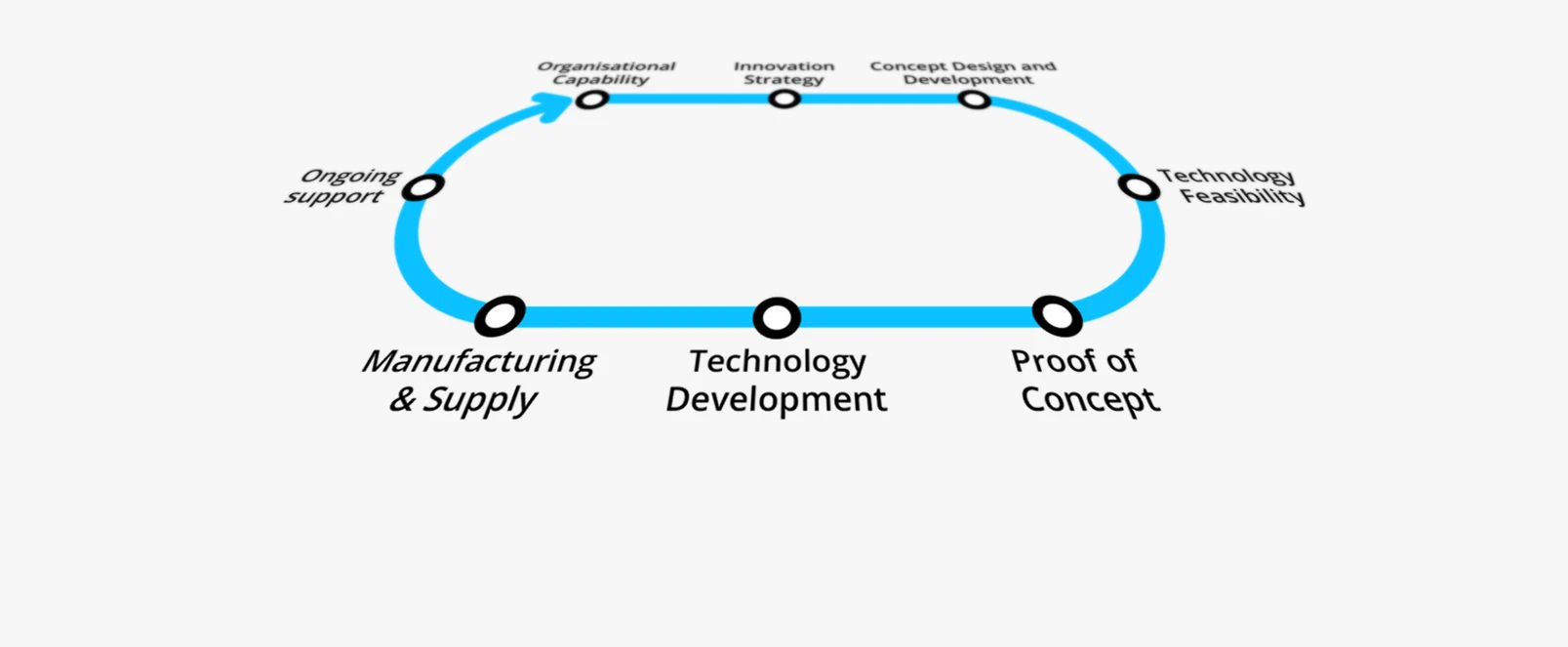

How we work

At Plextek, we have a proven track record of transforming innovative concepts into real-world solutions with precision and efficiency. Our process is precisely designed to guide your idea through every stage.