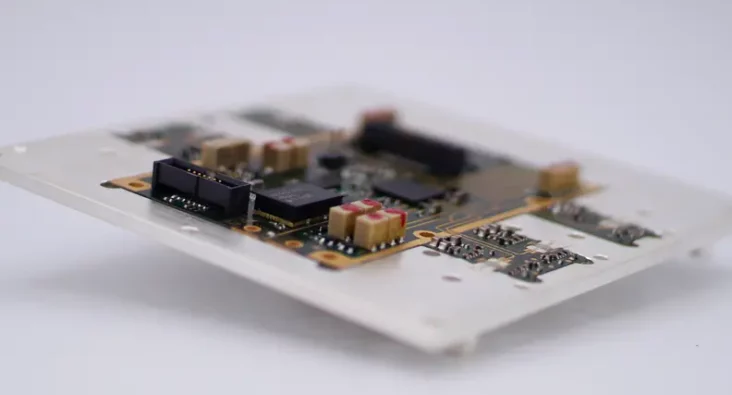

Space Electronics Design & Manufacturing

Engineering for space: where failure simply isn’t an option

The space environment presents challenges that would destroy conventional electronics within hours. We’ve spent years developing solutions that work reliably in conditions that push the boundaries of what’s physically possible.

What we do best

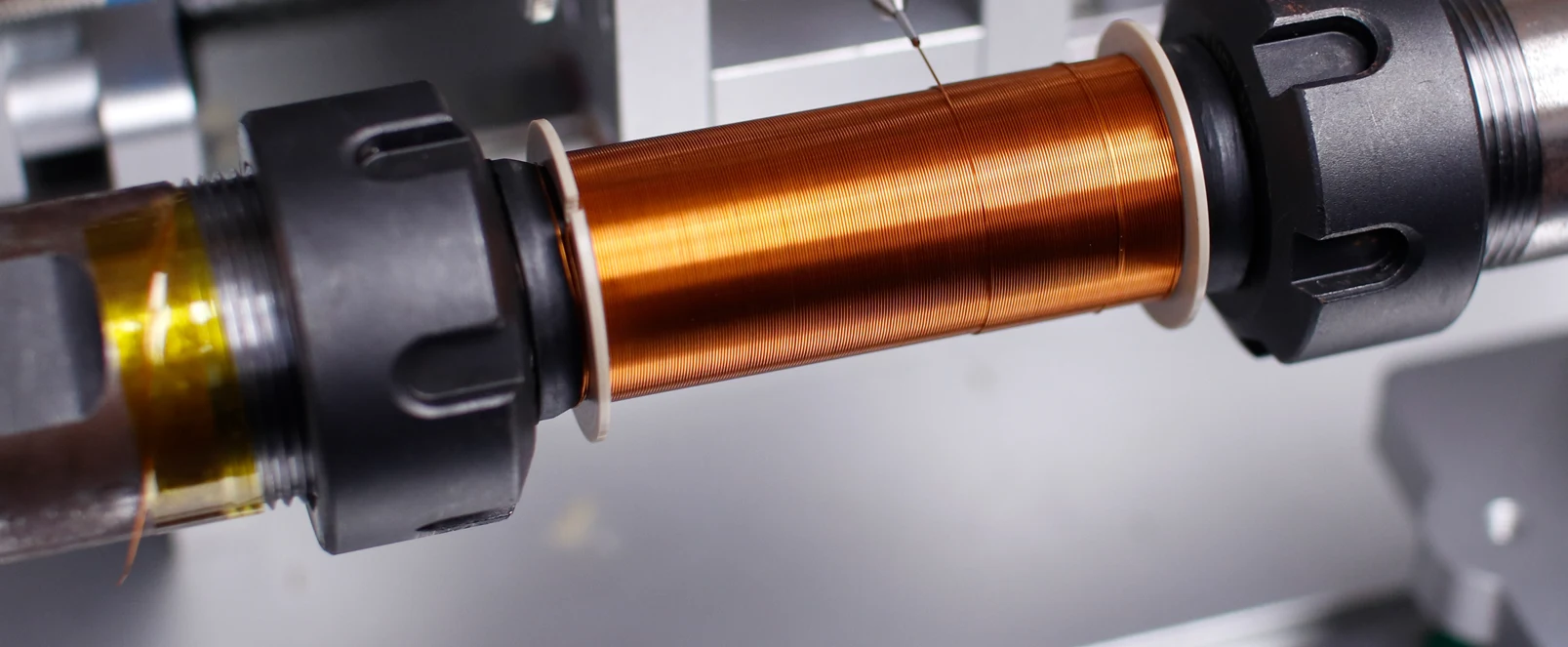

Component selection & qualification

Component specifications should consider factors like temperature range, vibration resistance, vacuum compatibility, and long-term reliability – complying with the relevant standards.

- Temperature optimisation (-200°C to +150°C)

- Vibration and shock resistance

- Vacuum compatibility and outgassing control

- Long-term reliability assessment

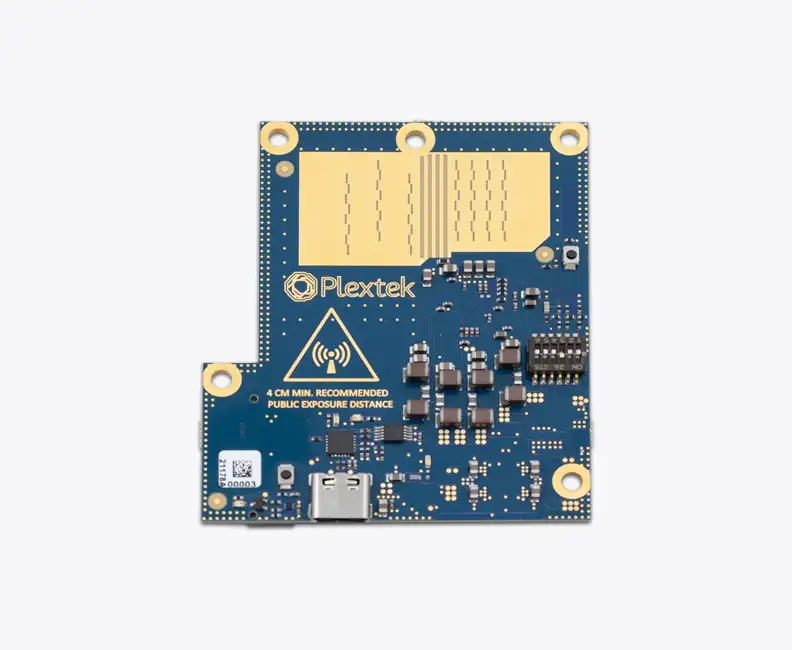

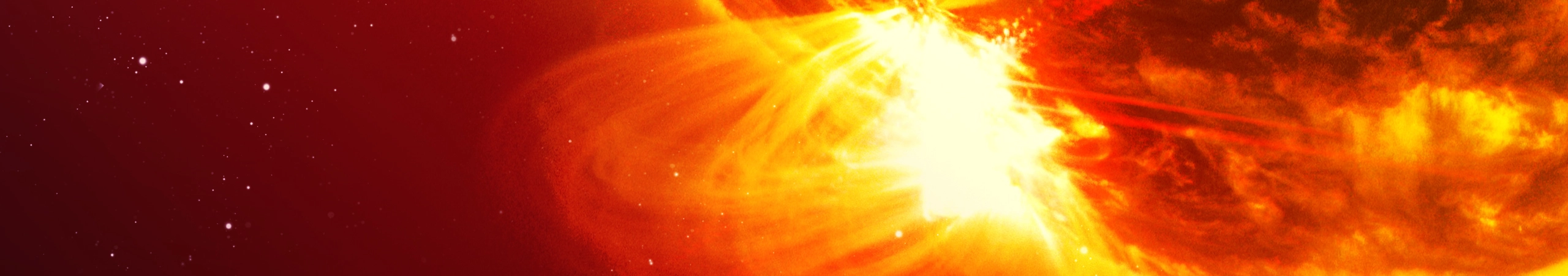

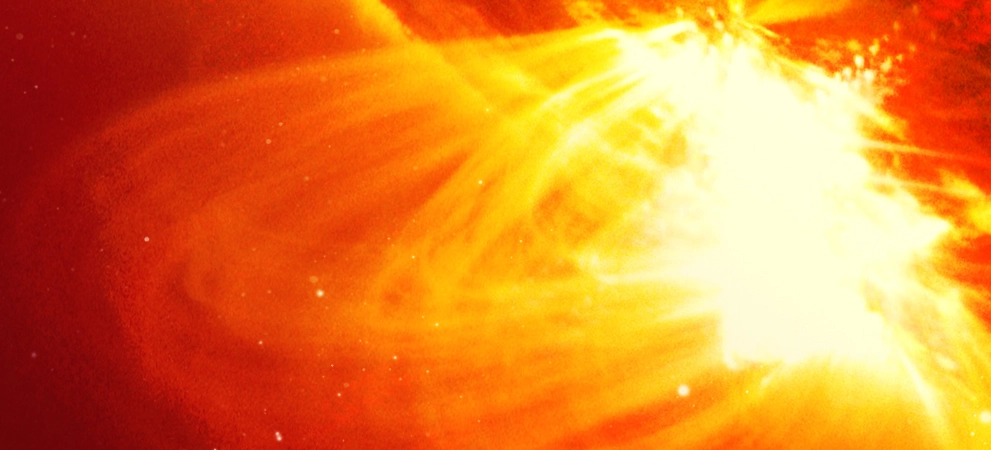

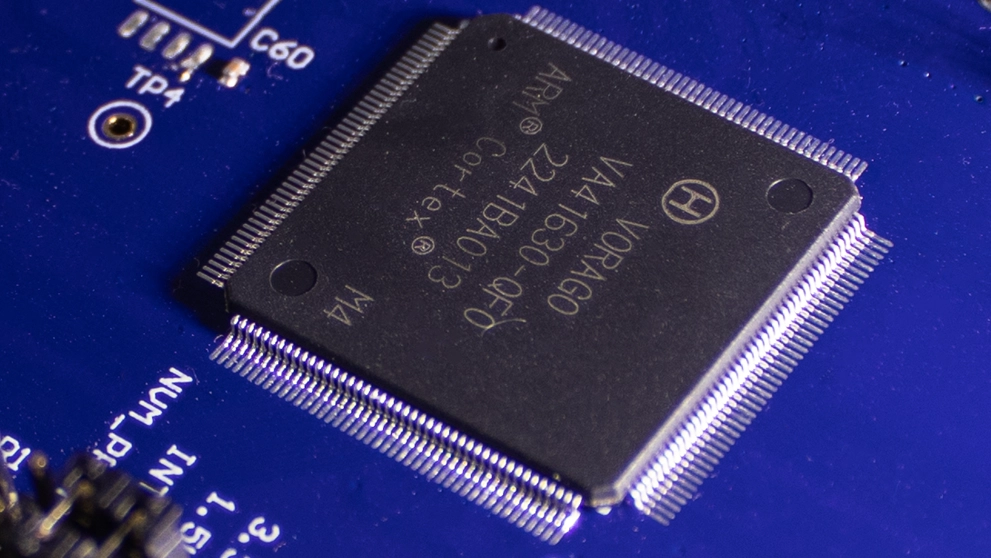

Radiation hardening solutions

Protecting electronics from solar and cosmic radiation.

A fundamental difference between terrestrial and space electronics is the requirement to withstand the increased solar and cosmic radiation that it will be exposed to. The impact of radiation can be mitigated by design considerations throughout a system’s development i.e. at the component / circuit / device / system-level.

Multi-level approach:

- At the component level specialist processes (such as Silicon on Insulator (SOI), Silicon Carbide, and GaN) can be used to reduce components’ susceptibility to charge. Components can also be selected that are pre-qualified for Total Ionizing Dose (TID) and Single Event Effects (SEE).

- At the circuit level sporadic events or glitches can be accommodated with approaches like temporal filtering or Triple Modular Redundancy (TMR) employing triplicate logic circuits with majority voting. Whilst timers, resets and current management are amongst the techniques for resisting and recovering from latching or hang-ups.

- Guard rings and general miniaturisation can provide device level protection, along with general shielding as well as the specific physical protection of critical components.

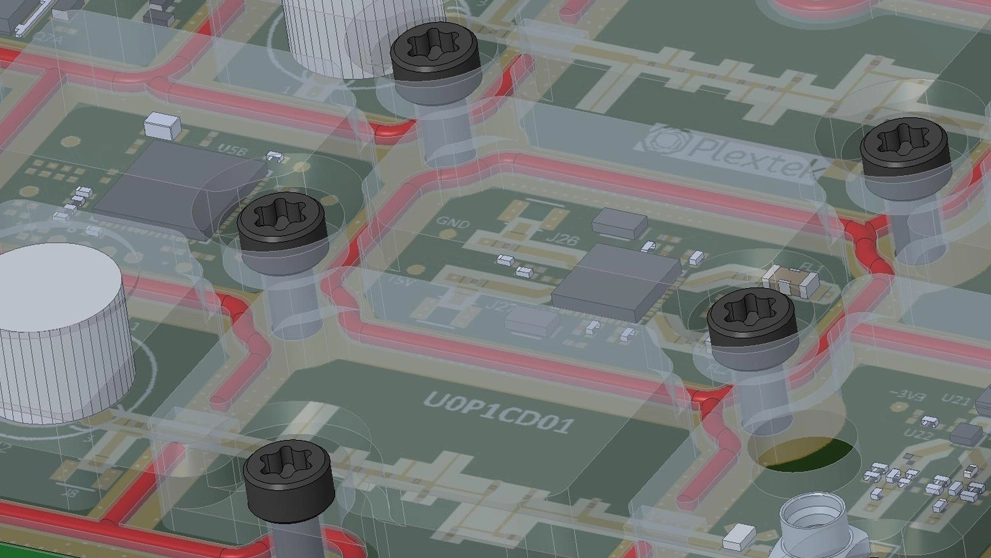

System-level reliability engineering

Building intelligence into every layer.

At a system level there are both hardware and software approaches to improve reliability

- Critical components and functions should be replicated to provide redundancy

- Hardware should be reconfigurable, such as scrubbing within FPGAs to enable repair following a SEE. A similar approach could be periodic reboots to prevent the accumulation of SEEs in software state

- Where damage can’t be prevented graceful degradation should be planned for such that partial failures don’t compromise the entire system

- Fault detection and correction within software via checksums and data integrity checks

- As described with hardware, voting between redundant computations can enable algorithmic fault detection

Out-of-this-world challenges

Ready to Start Your Space Project?

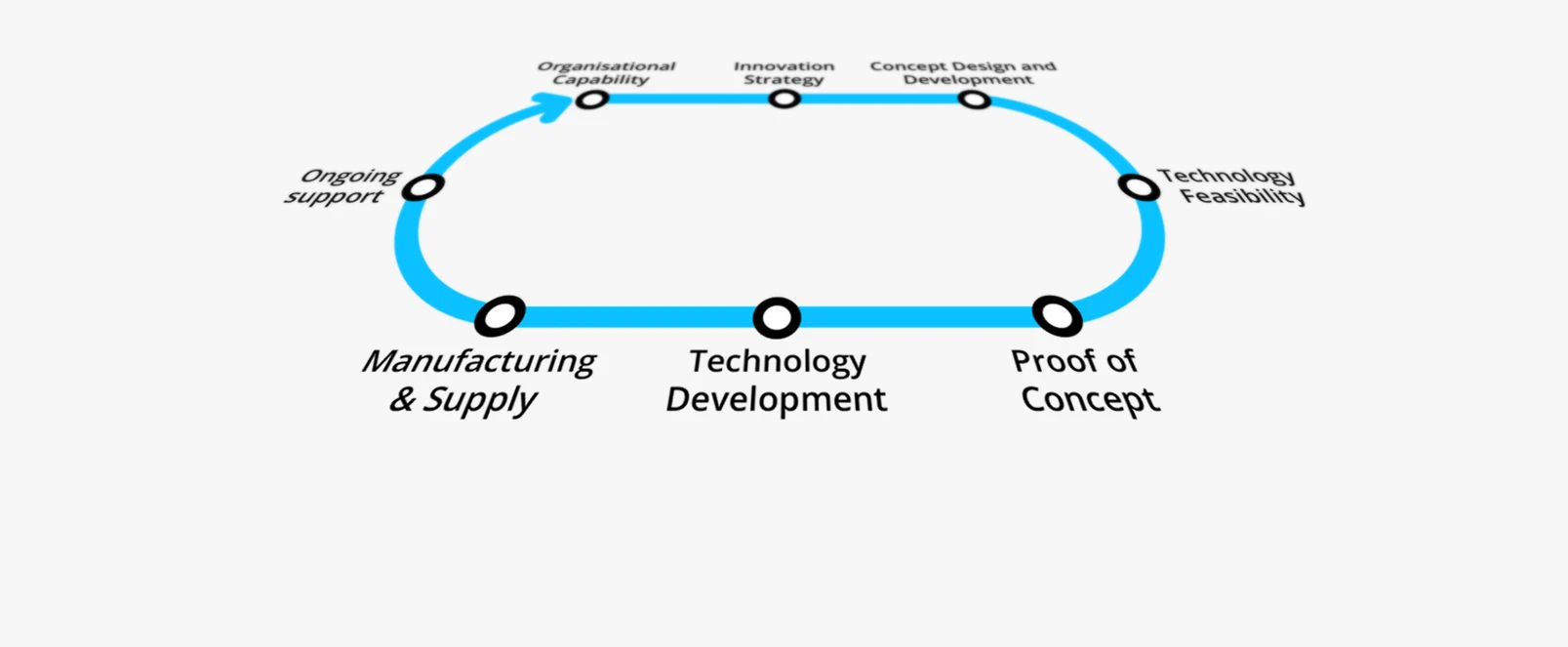

Initial chat

- Tell us about your mission requirements and challenges. We’ll discuss whether we’re a good fit and outline potential approaches.

Technical review

- Our engineers review your specifications and provide a preliminary assessment with realistic recommendations.

Detailed proposal

- Technical proposal including component selection, testing strategy, and fixed-price quotation where possible.