The Challenge

Plextek works on a range of complex hardware programmes and often delays of designing a single module can set back the whole project.

These challenging requirements mean that the appropriate technical expertise is not always widely available, making delays hard to recover from.

Design, manufacturing, test and supply chain resource are all required from the start to allow potential issues to be prevented and a concurrent engineering approach to be taken.

The Approach

We are quick to understand requirements and communicate these between design, project and quality assurance teams, becoming a valuable extension of our client’s design team.

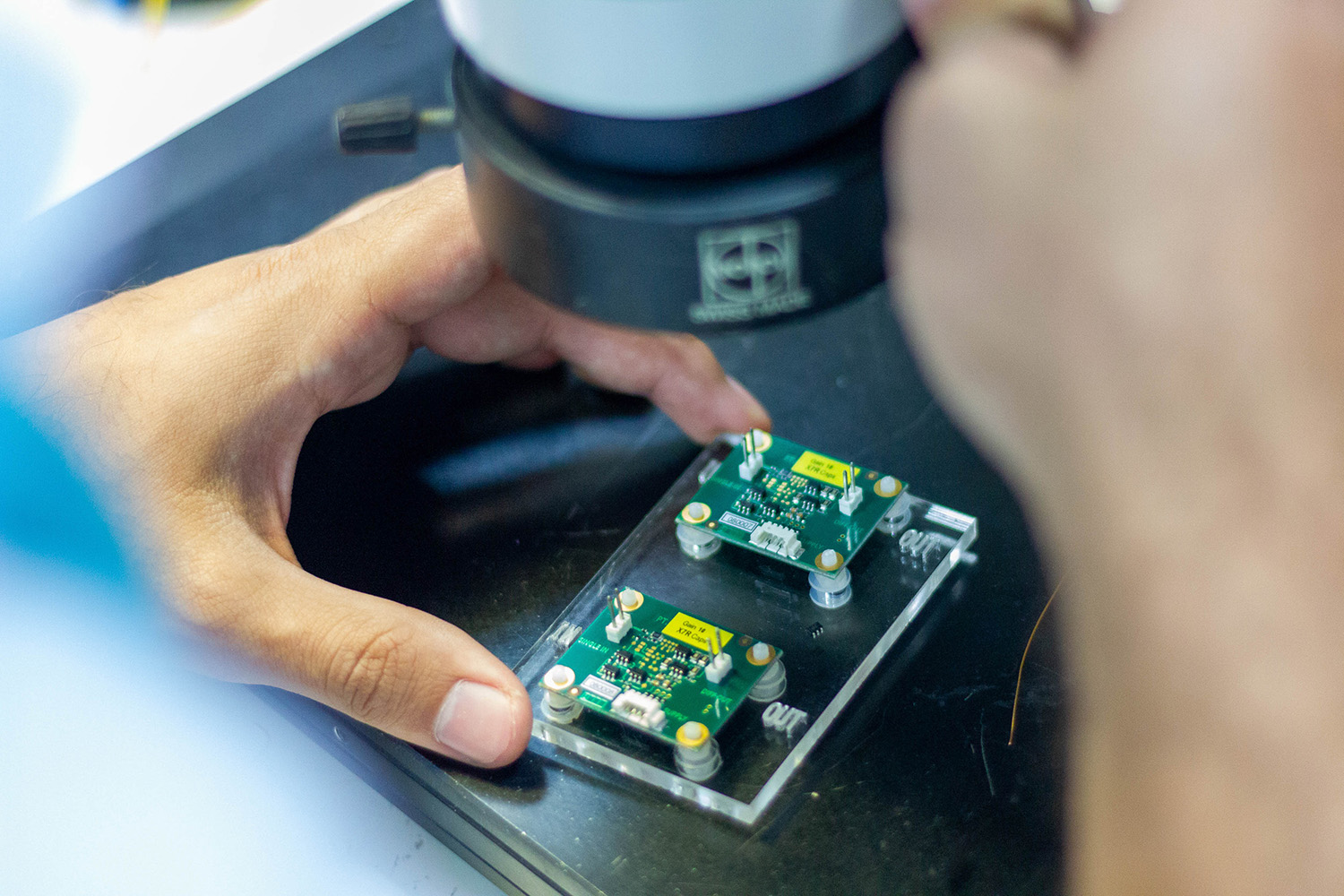

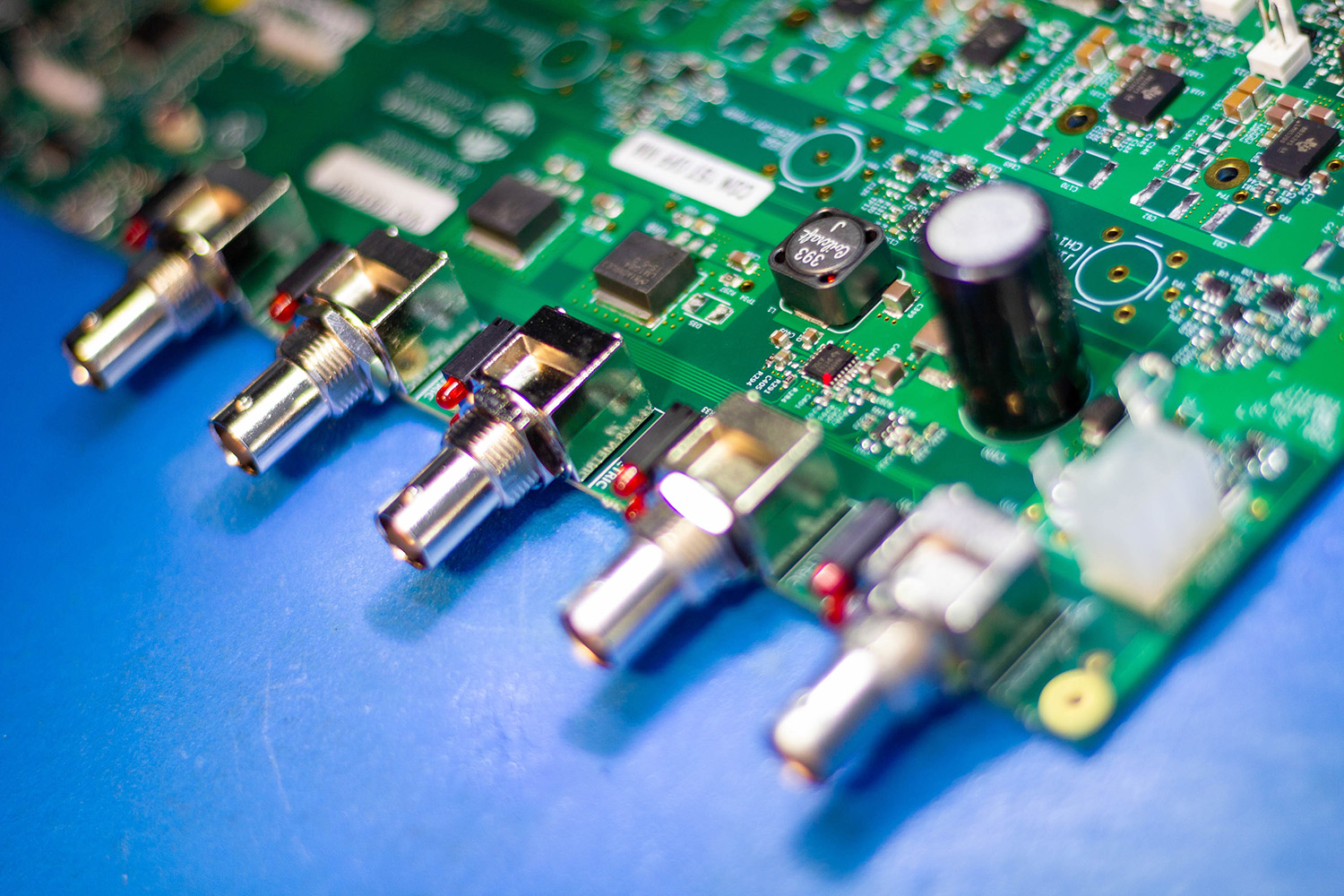

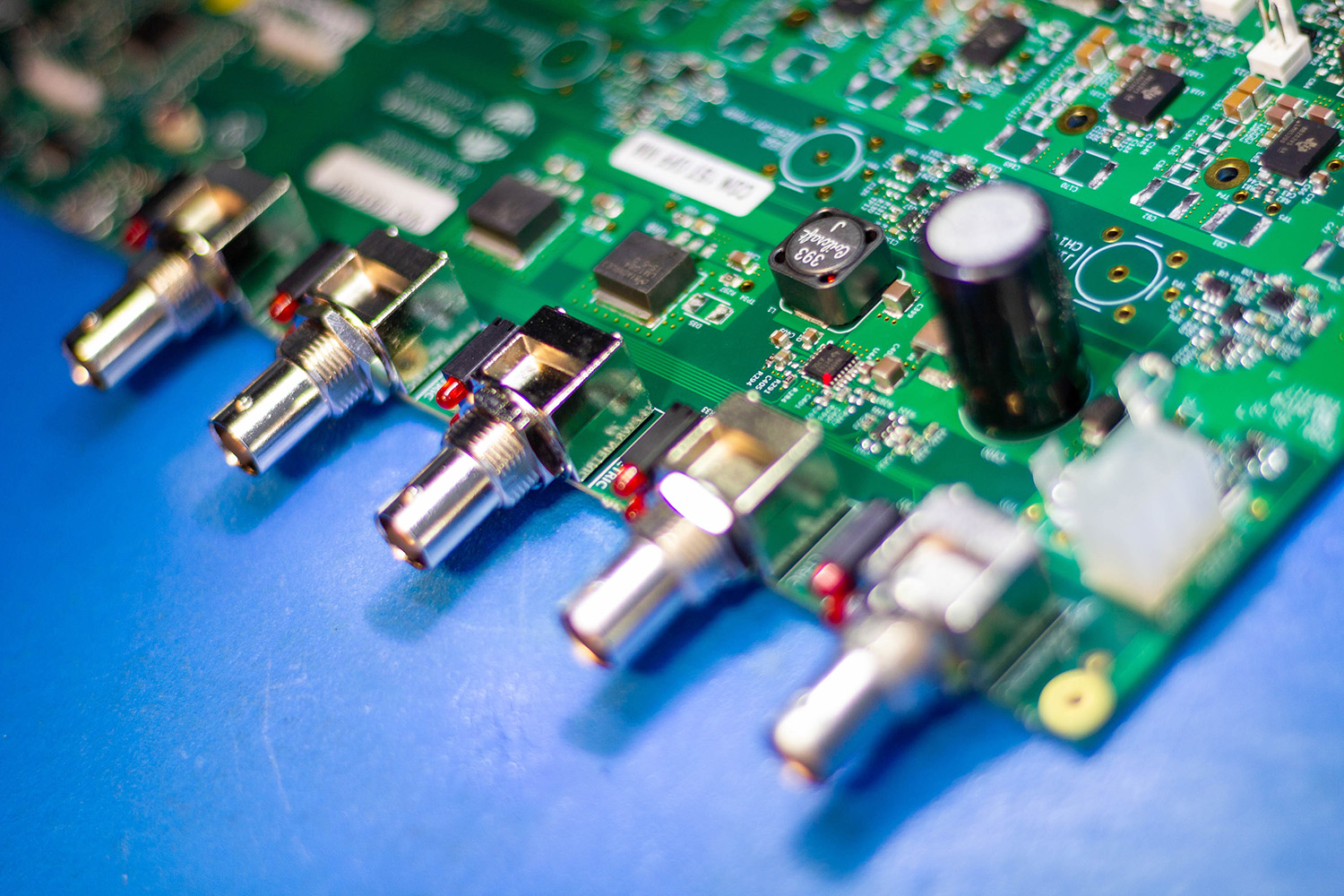

Our specialist manufacturing, test and supply chain engineers are involved from the start of every project. Manufacturing and test plans are then generated to provide a framework essential for robust design and supply.

As an independent company, we select, audit and test suppliers and materials based on evidence not ease.

The Approach

We are quick to understand requirements and communicate these between design, project and quality assurance teams, becoming a valuable extension of our client’s design team.

Our specialist manufacturing, test and supply chain engineers are involved from the start of every project. Manufacturing and test plans are then generated to provide a framework essential for robust design and supply.

As an independent company, we select, audit and test suppliers and materials based on evidence not ease.

The Outcome

Selecting the best resource for the requirement or working with existing suppliers, we’re able to share our knowledge of both low and high volume factory test systems to implement a solution that gets results.

We pride ourselves on delivering fully tested production hardware and take the strain of this process off clients by managing on-going issues, such as component obsolesce and changes to environmental legislation.